1.Introduction

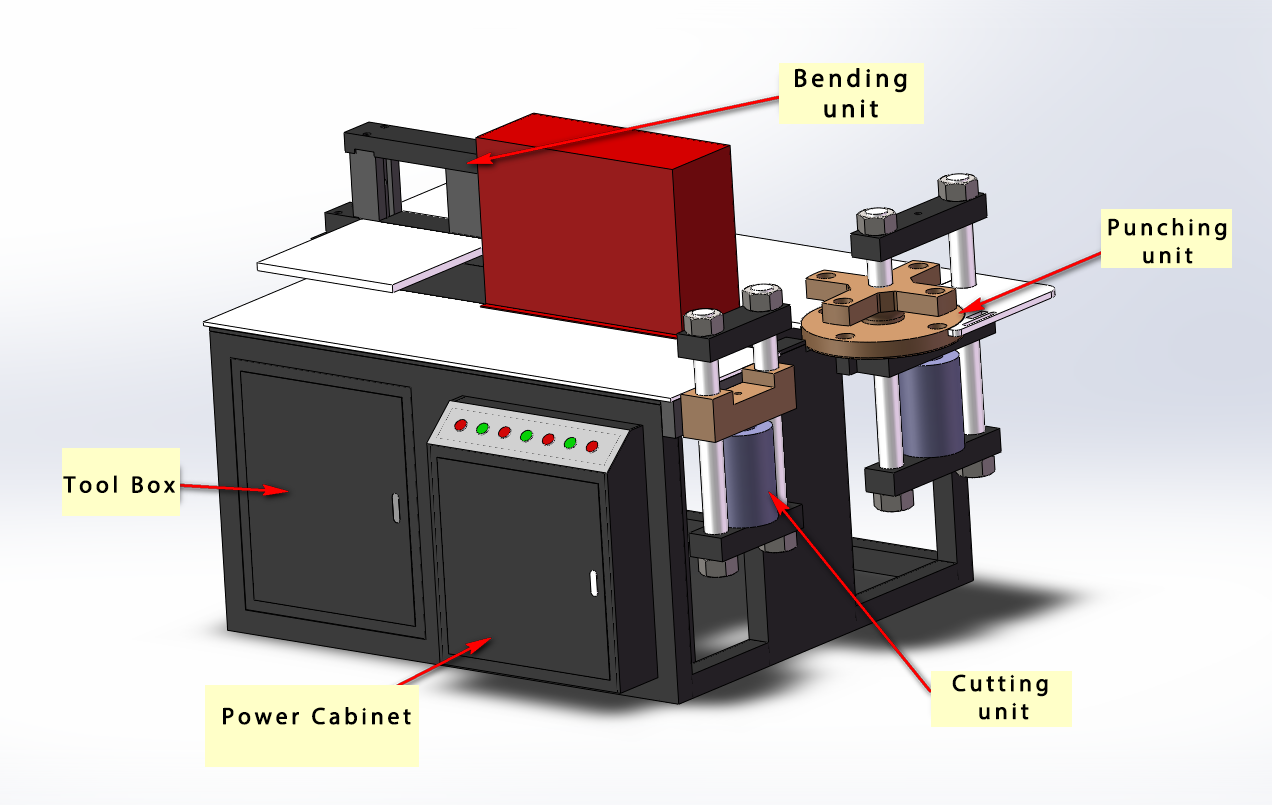

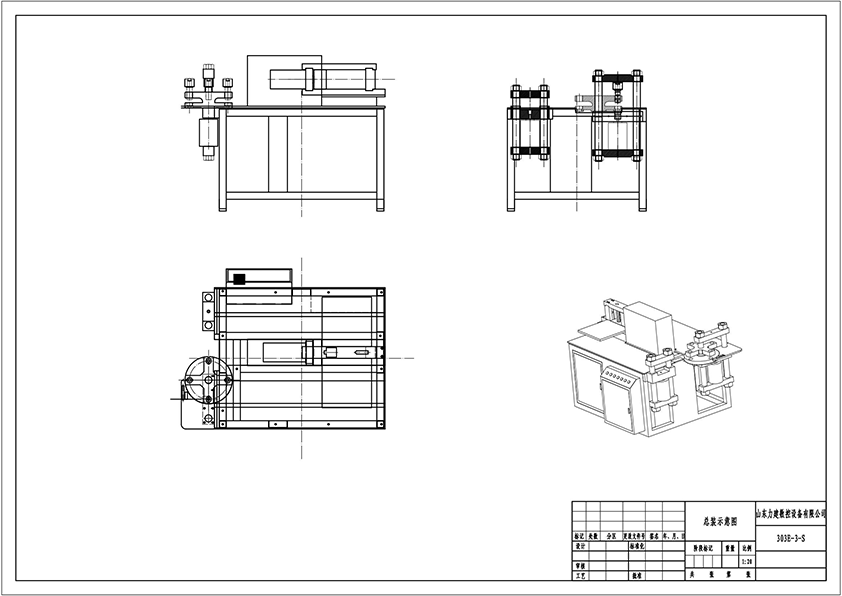

The machine is equipped with punching cutting bending three units, the three units can work at the same time, and will not influence each other. The punching unit is turret structure, the bending unit is closed on the top, the bending angle is with storage function. The main function is processing different types of copper (brass) aluminum bus bar. When it is working, workers just need to choose the unit, then machine will cutting and punching (holes,long holes square holes special holes), horizontal bending, vertical bending, embossing, leveling , twisting, and ect.

2.Main Characteristic

1.SIEMENS 40 PLC control system from German, which is with Automatic shutdown function, and can control the down time of cutting unit and punching unit, it is more stable and reliable than traditional relays.

2.Punching unit is with nodular-cast-ironed and turret typed turntable with 4/6/8 molds holes, which is a whole one, so that the holes for molds (the molds is processed by our processing center) with higher precision and the clearance of the molds and turntable is 0.00-0.03mm, improving the concentricity, then the life of molds can be longer and need not change the molds so frequently.

3.By added punching position, the machine can locate x axis and y axis mechanical double direction location. That makes workers don’t need cross lines and make punching marks, then improving the operating efficiency and accuracy of punching.

4.Cutting unit is with double upright pillars and double blades cutting structure (Patent NO.ZL201120262802.1) the above blade and below blade are installed vertically parallelly, make sure the cut smooth, no waste, no deformation for longtime used.

5.Bending unit is with closed bending, output point and force bearing force are connecting with beam of 50mm thickness, the mechanical strength is stronger than those open bending.

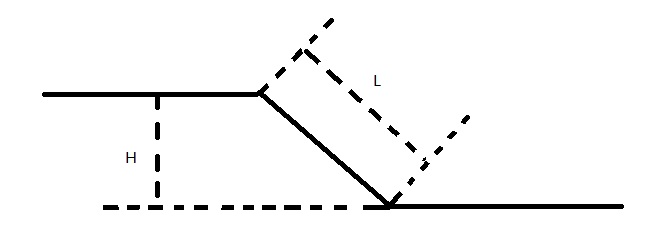

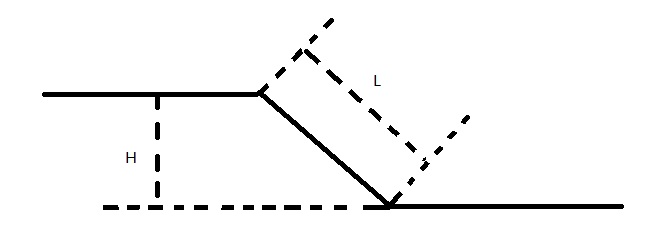

6.Bending angel is controlled by numerical control system. Z bending can be processed through enter H (vertical height of above and below planes) and L (length of Hypotenuse) (it can calculate the angel that needed itself). When it is working , workers just need enter the angel and the thickness for the busbar that needed then the machine can processing the parts conveniently and fast. And the machine is with storage function and error compensation.

7.Bending unit can processing U bending. The minimum distance is 40mm.

8.Hydraulic oil tank is welded by 3mm thickness steel plate, and with phosphating, making the hydraulic oil can be used longer and will not be deterioration.

9.The machine offers the oil one to one, three cylinders/three pumps, not influence each other.

10.Cylinder oil tubes are with international A type connection, durable and easy to repair.

11.The machine is with casters, easy to move.

3.Main parts:

| 1 | Main Motor | Juliweite | 3 |

| 2 | Hydraulic Oil Cylinder | LIJIAN (MADE IN TAIWAN, China) | 3 |

| 3 | Electromagnetic reversing valve | FENGYI | 3 |

| 4 | Electromagnetic relief valve | FENGYI | 3 |

| 5 | AC contactor | SIEMENS | 3 |

| 6 | Thermal relay | SIEMENS | 3 |

| 7 | PLC | SIEMENS | 1 |

| 8 | Encoder | GUANGYU | 1 |

| 9 | Touch screen | PanelMaster | 1 |

4.Random Annex:

Punching molds × 8(Φ7、Φ9、Φ11、Φ13、Φ17、Φ11×15、Φ13×17、Φ17×21)

Cutter × 1

Horizontal bending molds × 3

Embossing molds × 1

Random repair tool × 1

Standby seal ring × 1

Foot switch × 3

5.Parameter:

| Parameter | Value |

| Nominal Pressure | 350 kN |

| Maximum Cutting Size | 12 mm × 160 mm |

| Punching Size | Φ4.3 mm - Φ25 mm |

| Maximum Horizontal Bending Size | 12 mm × 160 mm |

| Maximum Vertical Bending Size | 12 mm × 120 mm |

| Workbench Maximum Size | First: 1500 mm × 1200 mm |

| Second: 940 mm × 420 mm | |

| Machine Size | 1750 mm × 1350 mm × 1500 mm |

| Machine Weight | 1390 kg |