I. Introduction:

This machine is a computer-controlled high-efficiency and high-precision special equipment for bus bar processing (6-axis numerical control), which is mainly used for fully-CNC punching and shearing of copper-aluminum busbar, including punching, shearing, corner cutting, embossing and other processes. Manual intervention is not needed during the processing of the bus bar, which has the advantages of high processing speed, high precision and the like, and is widely applied to the industries of high and low voltage complete sets, switch cabinets, box-type transformer substations and the like.

II. Main features:

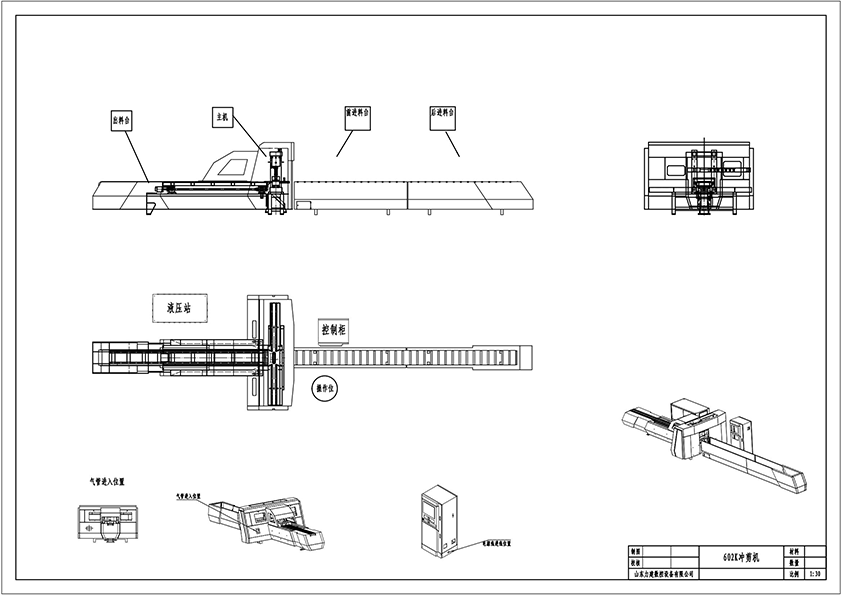

1. Feeding part:

The feeding part is equipped with the main and auxiliary power clamps of X1 and X2. The main clamp and the auxiliary clamp can operate independently and can be matched with each other to finish feeding work. This clamp structure avoids the situation that the auxiliary clamp of the same kind in China needs to be pushed back and forth by the main clamp servo when moving due to the lack of power of the auxiliary clamp, thereby leading to equipment failure and workpiece scrapping caused by bulging and bending of the small busbar during movement due to insufficient rigidity.

2. Mold movement part:

The mold movement part is in the spindle Y-axis and is mainly in the form of a servo motor driving ball screw to achieve reciprocating mold changing, thereby realizing the movement and positioning of the mold. The integral mold library has the characteristics of stable movement, accurate positioning and high speed.

3. Punch striking part: (Patent No.: ZL 2013 2 0804568. X)

The punch striking part is in the Z direction, and the servo motor drives the lead screw to move in the Z direction. The maximum strike speed is 150 beats per minute.

4. Mold library part: (Patent No.: ZL 2013 2 0804566.0; no waste materials after shearing, the only one in China)

The mold library part is a seven-punching-one-shearing-one-embossing or eight-punching-one-shearing in-line mold library. The shearing tool is a single-knife centering-type shearing, and the shearing effect is good without waste materials after shearing.

5. Hydraulic power part:

The hydraulic power part adopts double-speed double-pressure fast oil supply, with the maximum output of 600KN. The oil temperature sensor on the machine can accurately transmit the temperature of the oil to the radiator. When the temperature of the oil exceeds the set value, the radiator automatically starts to dissipate heat, ensuring the hydraulic system of the machine can run safely and effectively for a long time.

6. Electrical control part:

The advanced programmable controller of Beckhoff is adopted. During the working process, the point coordinate input mode can be selected for programming (it is simple to use and has low requirements for the operator). It can also realize the direct generation of CAD drawing to processing program, and can directly perform bending and unfolding operation and processing program simulation operation in the software.

7. LJCAM-02-2014.3 Programming Software: (Software Copyright Registration Certificate: 2014SR177566, originally obtained)

This software realizes the direct generation of CAD drawing to the machining program (the machining code is directly generated by the CAD drawing), and can directly perform bending and unfolding operation and processing program simulation operation in the software.

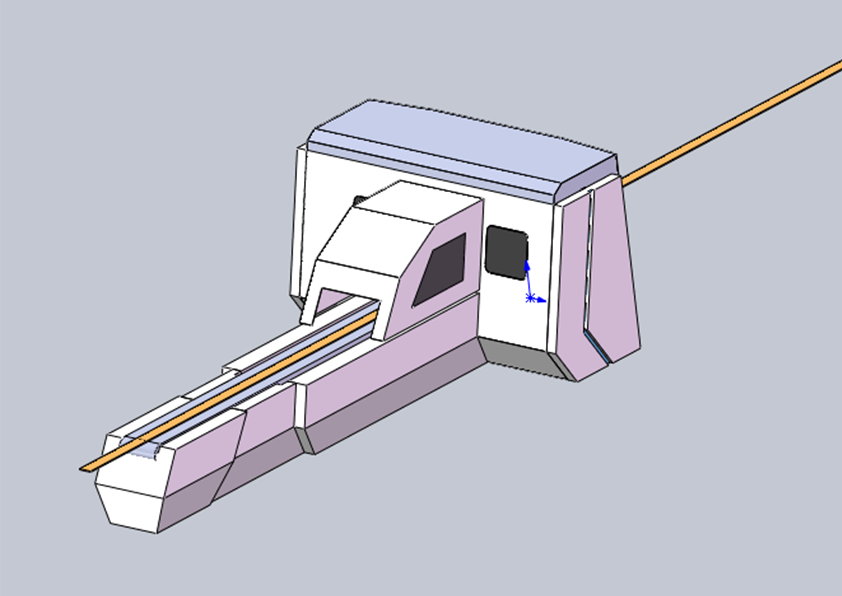

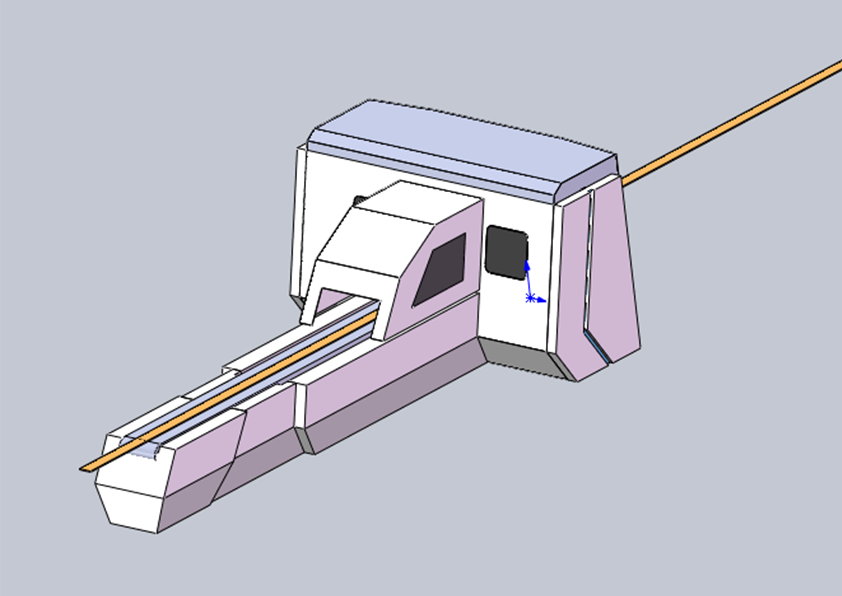

8. Appearance: The appearance design is novel and generous. (Patent No.: ZL 2014 3 0448531.8)

III. Main technical parameters:

| Number of mold positions | Punching unit | Piece | 7 | 8 |

| Shearing unit | Piece | 1 | 1 | |

| Embossing unit | Piece | 1 | 0 | |

| Beating frequency of main beating cylinder | HPM | 120-150bpm (20mm stroke) | ||

| Number of control axes | AXIS | 6 | ||

| Hole spacing control accuracy | mm/m | ±0.20 | ||

| Maximum punching diameter | mm | ?4.3-35 (circular hole) | ||

| Maximum cross-sectional area | mm2 | 200×50 | ||

| Maximum positioning speed of X-axis | m/min | 75 | ||

| Maximum effective stroke of X-axis | mm | 2000 | ||

| X-axis accuracy error | mm | 0.20/500 (not accumulated) | ||

| Maximum positioning speed of Y-axis | m/min | 40 | ||

| Maximum effective stroke of Y-axis | mm | 960 | ||

| Y-axis accuracy error | mm | 0.20/500 (not accumulated) | ||

| Maximum stroke of Z-axis | mm | 310 | ||

| Stroke of punching cylinder | mm | 45 | ||

| Maximum allowable size | mm | 6000×200×15 (L×W×D) | ||

| Minimum allowable size | mm | 15×3 (W×D) | ||

| Area of main station: | mm | 10500×2900 (L×W) | ||

| Total power of power supply | kW | 25 | ||

IV. Selection of main accessories:

| Electrical part: | |||||

| Serial No. | Name | Brand | Serial No. | Name | Brand |

| 1 | Main motor | ABB | 2 | Programmable controller | BECKHOFF, Germany |

| 3 | Servo motor | Rexroth | 4 | Intermediate relay | Honeywell |

| 5 | Servo driver | Rexroth | 6 | Computer | Beijing Qiyang |

| 7 | AC contactor | Siemens | 8 | Thermal relay | Siemens |

| 9 | DC power supply | Phoenix, Germany | 10 | Circuit breaker | Siemens |

| 11 | Inductive switch | BALLUFF, Germany | 12 | Linear displacement sensor | BALLUFF, , Germany |

| Transmission and hydraulic system: | |||||

| Serial No. | Name | Brand | Serial No. | Name | Brand |

| 1 | Electromagnetic reversing valve | Rexroth, Germany | 2 | Proportional valve | Rexroth, Germany |

| 3 | Precision ball screw | HIWIN/TBI | 4 | Precision linear guide rail | HIWIN/PEK |

| 5 | High pressure oil pump | Albert, the United States | |||

V. Accessories:

8 sets of punching dies, 1 pair of scissors, 1 pair of embossing dies, 1 set of maintenance tools, instructions and certificate of conformity.

RELATED

RELATED