I. Introduction:

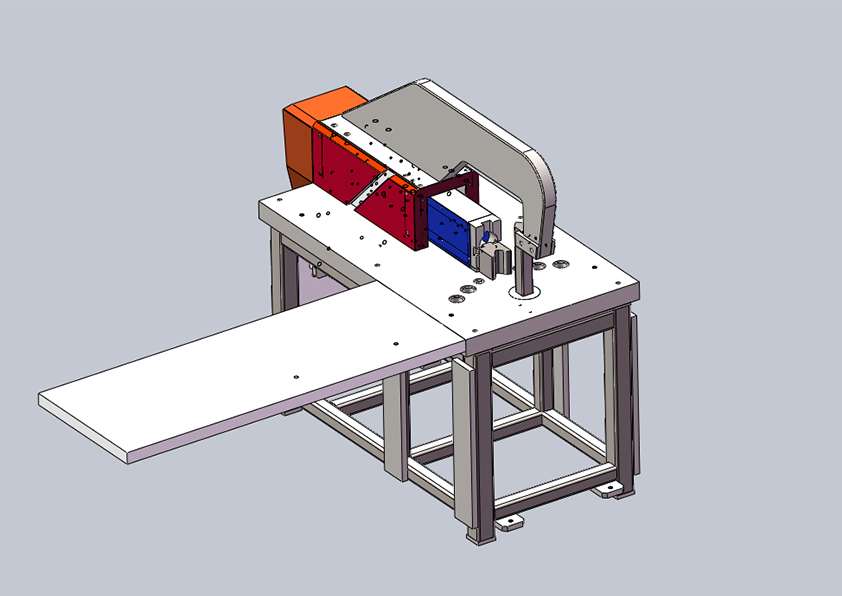

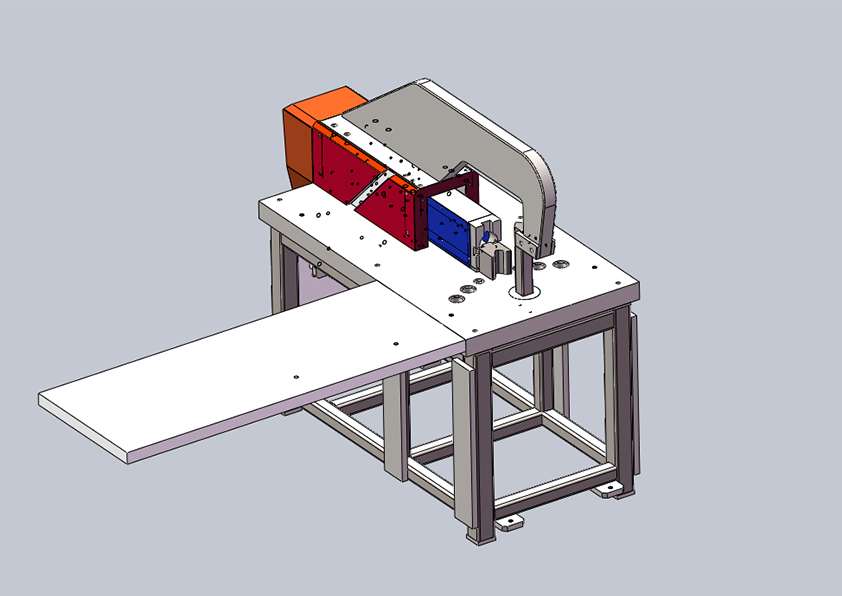

The NC.40ZB-2000 CNC busbar bending machine is an efficient, highly automated, and high-precision equipment used for bending copper and aluminum busbars. The machine is powered by servo motors, controlled by CNC units, and equipped with a self-developed CAD/CAM software system. This ensures that the machine's level of automation is at the forefront of the industry. It is an ideal equipment for busbar processing in industries such as complete sets of high and low voltage equipment, box-type substations, transformers, and busbar slots.

The machine adopts large inertia servo motor as the main power to provide transmission power for high-precision planetary reducer and grinding ball screw.

Compared with the traditional hydraulic bending machine, it has the following advantages:

1.The transmission is stable, the repeated positioning precision is high, the precision is not influenced by the temperature, and the stability is higher.

2.Automatic stop function is available in standby mode, which greatly reduces working energy consumption.

3.The machine adopts servo motor as power, solving the trouble of oil leakage caused by hydraulic transmission.

4.When working, the sound of the servo motor is low, reducing the noise pollution.

5.It has the centering capacity carrying mode, and the linear guide, which balance the stress, and reduce the influence of eccentric load and friction on the service life and processing precision of the lead screw.

6.The material stopping ruler is divided into three gears, which can be adjusted manually according to the processing technology, thereby greatly improving the working efficiency.

II. Selection of main accessories:

| 1 | Servo motor | Rexroth | 1 pc. | 2 | Spindle lead screw | Nanjing Technological Equipment | 1 pc. |

| 3 | Precision planetary speed reducer | TECHMECH | 1 pc. | 4 | Linear guide | HIWIN/PEK | 5 pcs |

| 5 | AC contactor | Siemens, Germany | 1 pc. | 6 | Computer | Beijing Qiyang | 1 pc. |

| 7 | Positioning lead screw | TBI, Taiwan | 1 pc. | 8 | Industrial switch | TP-LINK | 1 pc. |

| 9 | Programmable controller | Beckhoff, Germany | 1 pc. | Blank here | |||

III. Parameter comparison:

| 1 | Nominal pressure | KN | 400 | 2 | Spindle motor power | KW | 7.5 |

| 3 | Bending accuracy | ° | ±0.3 | 4 | Spindle stroke | mm | 200 |

| 5 | Material blocking accuracy | mm | ±0.15 | 6 | Maximum size of flat bending | mm | 15×200 |

| 7 | Maximum size of vertical bending | mm | 12×120 | 8 | Material blocking length | mm | 2000 |

| 9 | Machine weight | KG | 3300 | 10 | Appearance and size | mm | 4300×1450×1850 |

IV. Accessories:

| 1 | Flat bending core | R5 | 1 pc. | 2 | Flat bending core | R10 | 1 pc. | 3 | Flat bending cavity | 50mm | 1 pc. |

| 4 | Flat bending cavity | 80mm | 1 pc. | 5 | Vertical bending core | R30 | 1 pc. | 6 | Vertical bending core | R100 | 1 pc. |

| 7 | Vertical bending inserting shaft | 4 pcs. | 8 | Accompanying tools | 1 set | Blank below | |||||

V. Quality Service:

1.The warranty period is one year. In case of any quality problem within the warranty period, the on-site service shall be provided unconditionally within 24 hours.

2.All mold parts are guaranteed for three months. In case of quality problems within three months, they shall be returned or replaced unconditionally.

3.We provide free delivery, and free debugging training until the mastering of the machine.

RELATED

RELATED