The Role of Busbar processing machines in Switchgear Assembly

Introduction

Switchgear is an essential component in electrical power systems, providing protection, control, and isolation of electrical equipment. It ensures the safe and efficient distribution of electrical power across various applications, from industrial plants to residential buildings. One of the critical elements in switchgear assembly is the busbar system, which acts as a conductor for electrical current. The precision and quality of busbar processing directly impact the performance, reliability, and safety of switchgear. Busbar processing machines play a pivotal role in ensuring that busbars are manufactured to exact specifications, meeting the stringent requirements of modern electrical systems. This article explores the role of busbar processing machines in switchgear assembly, detailing their functions, benefits, and the impact they have on the overall quality of switchgear.

Understanding Busbars and Their Importance in Switchgear

Busbars are metallic strips or bars, typically made of copper or aluminum, that conduct electricity within switchgear, distribution boards, and other electrical systems. They serve as a central hub for distributing power to various circuits and components. The design and fabrication of busbars are critical because they must handle high currents, resist thermal and mechanical stresses, and maintain electrical continuity under varying conditions.

In switchgear, busbars are used to connect circuit breakers, transformers, and other devices, ensuring a reliable flow of electricity. The quality of busbars directly affects the efficiency, safety, and longevity of the switchgear. Poorly fabricated busbars can lead to overheating, electrical faults, and even catastrophic failures. Therefore, precision in busbar processing is non-negotiable.

The Role of Busbar Processing Machines

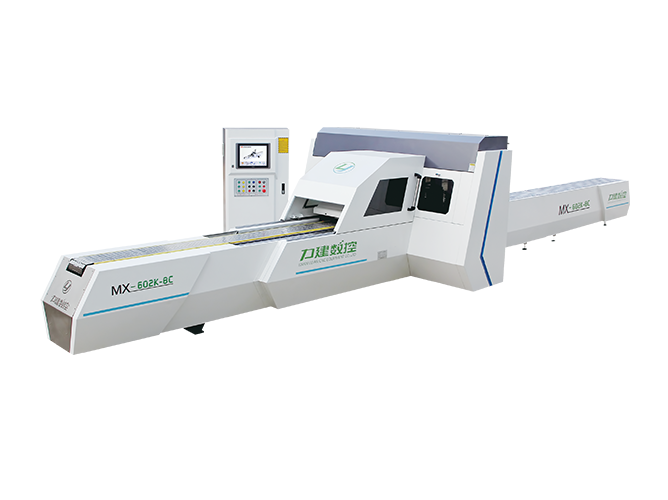

Busbar processing machines are specialized equipment designed to automate and streamline the fabrication of busbars. These machines perform a range of operations, including cutting, punching, bending, and marking, with high precision and efficiency. Their role in switchgear assembly is multifaceted, encompassing the following key functions:

1. Precision Cutting

Busbars must be cut to specific lengths to fit the dimensions of the switchgear. Manual cutting methods are prone to errors and inconsistencies, which can compromise the integrity of the busbar system. Busbar processing machines use advanced cutting technologies, such as CNC (Computer Numerical Control) systems, to ensure precise and repeatable cuts. This eliminates material waste and ensures that each busbar meets the required specifications.

2. Accurate Punching

Punching holes in busbars is necessary for mounting them in switchgear and connecting them to other components. Manual punching is labor-intensive and can result in misaligned or improperly sized holes. Busbar processing machines automate this process, using CNC-controlled punching tools to create holes with exact dimensions and positions. This ensures proper alignment and secure connections within the switchgear.

3. Complex Bending

Busbars often need to be bent into specific shapes to fit the layout of the switchgear. Manual bending is challenging, especially for complex geometries, and can lead to inaccuracies. Busbar processing machines use precision bending tools to achieve consistent and accurate bends, even for intricate designs. This capability is crucial for optimizing the use of space within the switchgear and ensuring proper electrical connections.

4. Marking and Labeling

Proper identification of busbars is essential for maintenance and troubleshooting. Busbar processing machines can automatically mark or label busbars with relevant information, such as part numbers, ratings, or installation instructions. This reduces the risk of errors during assembly and simplifies future maintenance tasks.

5. Material Handling and Efficiency

Busbar processing machines are designed to handle large volumes of material efficiently. They can process multiple busbars in a single operation, significantly reducing production time. Automated material handling systems, such as conveyors and feeders, further enhance efficiency by minimizing manual intervention and reducing the risk of damage to the busbars.

Benefits of Using Busbar Processing Machines in Switchgear Assembly

The use of busbar processing machines offers numerous benefits in switchgear assembly, including:

1. Enhanced Precision and Quality

Busbar processing machines ensure that each busbar is fabricated to exact specifications, eliminating human errors and inconsistencies. This results in higher-quality busbars that meet the stringent requirements of switchgear systems.

2. Increased Productivity

Automation of busbar processing significantly reduces production time, allowing manufacturers to meet tight deadlines and handle large orders efficiently. This is particularly important in industries where switchgear is in high demand.

3. Cost Savings

By minimizing material waste and reducing labor costs, busbar processing machines contribute to overall cost savings. The precision of these machines also reduces the likelihood of costly rework or repairs due to fabrication errors.

4. Improved Safety

Manual busbar processing involves risks such as cuts, burns, and exposure to sharp edges. Busbar processing machines eliminate these hazards by automating the most dangerous tasks, creating a safer working environment for operators.

5. Versatility

Modern busbar processing machines are highly versatile, capable of handling a wide range of materials, thicknesses, and designs. This flexibility allows manufacturers to produce busbars for various types of switchgear, from low-voltage systems to high-voltage applications.

6. Consistency and Repeatability

Automated busbar processing ensures that every busbar is identical, which is critical for the reliable performance of switchgear. Consistency and repeatability are particularly important in large-scale production, where even minor deviations can lead to significant issues.

Impact on Switchgear Assembly

The integration of busbar processing machines into switchgear assembly has a profound impact on the entire manufacturing process. By ensuring the precision and quality of busbars, these machines contribute to the overall reliability and performance of switchgear. Here are some specific ways in which busbar processing machines influence switchgear assembly:

1. Streamlined Production Workflow

Busbar processing machines integrate seamlessly into the production workflow, reducing bottlenecks and ensuring a smooth assembly process. This integration minimizes downtime and maximizes efficiency, allowing manufacturers to meet production targets with ease.

2. Customization and Flexibility

The ability to produce custom busbars quickly and accurately enables manufacturers to cater to specific customer requirements. This flexibility is particularly valuable in industries where switchgear must be tailored to unique applications or environments.

3. Enhanced Reliability of Switchgear

High-quality busbars fabricated by processing machines contribute to the overall reliability of switchgear. Reliable busbars reduce the risk of electrical faults, overheating, and other issues that can compromise the performance of the system.

4. Scalability

Busbar processing machines are scalable, meaning they can handle both small and large production volumes. This scalability is essential for manufacturers who need to adapt to fluctuating market demands.

5. Compliance with Industry Standards

Switchgear must comply with stringent industry standards and regulations to ensure safety and performance. Busbar processing machines help manufacturers meet these standards by producing busbars that adhere to precise specifications.

Challenges and Considerations

While busbar processing machines offer numerous advantages, there are some challenges and considerations that manufacturers must address:

1. Initial Investment

The cost of purchasing and installing busbar processing machines can be significant. However, the long-term benefits in terms of productivity, quality, and cost savings often justify the investment.

2. Training and Skill Development

Operating busbar processing machines requires specialized skills and training. Manufacturers must invest in training programs to ensure that operators can use the machines effectively and safely.

3. Maintenance and Upkeep

Like any machinery, busbar processing machines require regular maintenance to ensure optimal performance. Manufacturers must establish a maintenance schedule and allocate resources for repairs and upgrades.

4. Integration with Existing Systems

Integrating busbar processing machines into an existing production line can be complex. Manufacturers must carefully plan the integration process to minimize disruptions and maximize efficiency.

Future Trends in Busbar Processing Technology

The field of busbar processing is continually evolving, driven by advancements in technology and the growing demand for high-quality switchgear. Some of the key trends shaping the future of busbar processing machines include:

1. Increased Automation

The trend toward greater automation is expected to continue, with machines becoming more intelligent and capable of handling complex tasks with minimal human intervention.

2. Integration with Industry 4.0

Busbar processing machines are increasingly being integrated into Industry 4.0 frameworks, enabling real-time monitoring, data analysis, and predictive maintenance. This integration enhances efficiency and reduces downtime.

3. Sustainability

As environmental concerns grow, manufacturers are seeking ways to make busbar processing more sustainable. This includes using energy-efficient machines, recycling materials, and minimizing waste.

4. Advanced Materials

The development of new materials with superior electrical and thermal properties is driving innovation in busbar processing. Machines must adapt to handle these materials while maintaining precision and quality.

Conclusion

Busbar processing machines play a critical role in the assembly of switchgear, ensuring the precision, quality, and efficiency of busbar fabrication. By automating key processes such as cutting, punching, bending, and marking, these machines enhance the reliability and performance of switchgear systems. The benefits of using busbar processing machines include increased productivity, cost savings, improved safety, and the ability to meet stringent industry standards. As technology continues to advance, busbar processing machines will become even more integral to the switchgear manufacturing process, driving innovation and enabling manufacturers to meet the growing demands of the electrical industry.

Comente

(0)