Top Features to Look for in a Busbar Punching and Shearing Machine

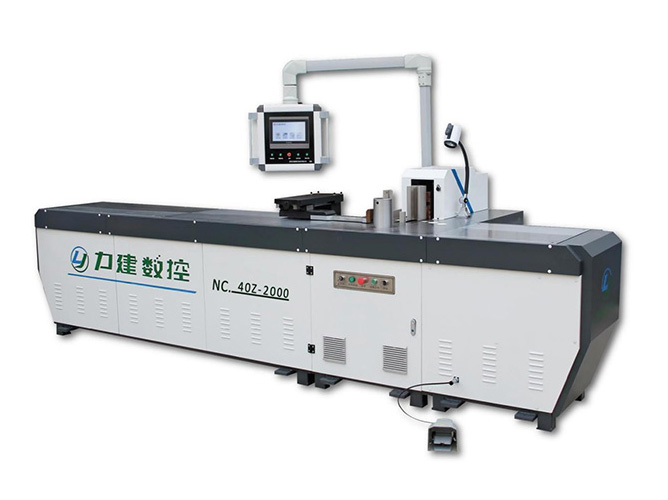

In the world of industrial manufacturing, the role of the Busbar Punching and Shearing Machine is critical for the production of electrical busbars. These machines combine precision, speed, and cost-efficiency to streamline operations. But with many options available, choosing the right machine requires an understanding of key features that can optimize performance. Whether you’re involved in electrical infrastructure, automotive manufacturing, or heavy industry, knowing what to look for in a busbar punching and shearing machine can make a significant difference in the long-term efficiency and profitability of your business.

Precision is perhaps the most important feature to consider in any busbar punching and shearing machine. The busbars must be cut to exact measurements to ensure that they fit perfectly in electrical systems or structures. Here’s why precision is essential:

Enhanced Performance: A machine that ensures precise cuts will enhance the overall performance of the electrical systems, reducing potential issues such as overheating or malfunctioning.

Reduced Material Wastage: Precision also means that you use less material, saving money on raw materials. With exact measurements, the risk of waste is minimized, which is both cost-effective and environmentally friendly.

When selecting a busbar punching and shearing machine, look for one with advanced CNC technology and high-quality tooling that guarantees tight tolerances and repeatability.

Efficiency in manufacturing is key to keeping production costs low and meeting deadlines. High-speed operation allows manufacturers to produce more busbars in less time, improving throughput without compromising on quality.

Fast Processing Time: Modern machines feature high-speed motors, faster punching and shearing cycles, and advanced automation, allowing you to process large quantities of busbars rapidly.

Increased Productivity: The ability to complete tasks faster means that you can increase the number of units produced per hour or per shift, thus increasing overall productivity. This is essential for industries with large-scale production demands.

Look for machines that offer customizable speed settings, so you can optimize the machine’s speed according to the specific requirements of your production line.

Busbars are made from various metals, including copper, aluminum, and steel. A versatile machine that can handle different materials and thicknesses is crucial for diverse production needs.

Multi-Material Handling: Some Busbar Punching and Shearing Machines come with specialized tooling and adjustments that allow them to handle a wide range of materials. This reduces the need for multiple machines for different materials.

Adjustable for Different Sizes: Busbars come in various dimensions depending on the project. A machine that can handle multiple sizes and thicknesses without requiring major modifications is essential for flexibility in production.

Ensure that the machine you select has adjustable tools or an adaptive feeding system that allows it to process different sizes of busbars easily.

Modern manufacturing requires machines that integrate seamlessly into automated production lines. A Busbar Punching and Shearing Machine with advanced automation capabilities reduces labor costs and minimizes human error.

Automatic Feeding Systems: Look for machines with automatic feeding systems that eliminate the need for manual loading, reducing operator intervention and increasing the overall efficiency of the production process.

Automated Quality Control: Some machines feature built-in quality control systems that can detect and correct imperfections as they arise during production. This ensures that only high-quality products leave the production line, minimizing defects and waste.

Automation not only improves productivity but also enhances consistency, making it an essential feature for large-scale production operations.

The ability to execute various punching and shearing operations is another critical feature. Busbar punching and shearing machines must be capable of handling a variety of operations without requiring significant downtime or changeovers.

Punching and Shearing Capabilities: Machines that can perform both punching and shearing tasks with high efficiency are preferable. Whether you need to create holes for mounting or cut busbars into precise lengths, a machine with dual capabilities will save you time and space.

Multiple Tooling Options: Machines with adjustable dies and tooling that can accommodate different punching patterns, hole sizes, and cutting profiles are highly beneficial. This allows you to handle a wide variety of busbar designs and requirements without needing multiple machines.

Choosing a machine that can perform multiple operations enhances flexibility, reduces operational costs, and allows for faster project turnaround times.

In a competitive manufacturing environment, controlling costs is essential for maintaining profitability. A busbar punching and shearing machine that offers energy-efficient operations can reduce operating costs significantly.

Energy-Saving Technologies: Look for machines with advanced energy-saving features such as variable frequency drives (VFDs), which regulate the machine’s motor speed according to the workload. This helps to minimize energy consumption during low-demand periods.

Low Maintenance Requirements: Machines with high-quality components and robust construction tend to have lower maintenance needs. Less frequent maintenance translates into fewer production delays and lower long-term costs.

Machines that integrate energy-saving technologies and require minimal maintenance can provide excellent return on investment (ROI) by reducing operational costs.

The harsh conditions of industrial environments mean that durability is a critical feature to consider. A busbar punching and shearing machine should be designed to withstand the rigors of continuous use.

Strong Frame Construction: The machine’s frame should be made from high-quality, durable materials, such as steel, to ensure long-term reliability and minimize the need for repairs.

Long Service Life: Machines designed with high-strength components and quality finishes will last longer, reducing the need for replacements and extending the lifespan of the equipment.

A durable machine is an investment that ensures you get the most value over time, providing uninterrupted service even in demanding manufacturing environments.

A machine with a complex interface can slow down production and lead to operator errors. Look for machines with an intuitive, easy-to-use interface that simplifies operation.

Touchscreen Controls: Modern Busbar Punching and Shearing Machines often come with touchscreen interfaces that make it easier to set parameters, adjust operations, and monitor the machine’s performance.

Simple Setup and Programming: Machines with automated setup features, such as automatic adjustment of punching depth and shearing length, can reduce setup times and make it easier for operators to manage different production jobs.

A user-friendly interface allows operators to make changes quickly and accurately, enhancing productivity and reducing the chances of human error.

Safety is paramount in any manufacturing environment. The presence of safety features on a busbar punching and shearing machine not only protects operators but also ensures compliance with industry standards.

Emergency Stop Functionality: A reliable emergency stop mechanism that halts the machine in case of unexpected issues or malfunctions is essential for protecting both the operator and the machine.

Guarding and Safety Sensors: Machines should be equipped with safety guards and sensors to prevent accidental contact with moving parts. This ensures the well-being of the operator while maintaining smooth production flow.

Machines that prioritize safety will help reduce the risk of workplace accidents and create a safer working environment.

After purchasing a busbar punching and shearing machine, it’s important to have access to robust support and maintenance services. Regular servicing ensures the machine operates optimally for years.

Comprehensive Maintenance Programs: Look for manufacturers that offer maintenance services, including preventive maintenance, troubleshooting, and replacement parts.

Training and Technical Support: Many manufacturers provide operator training and technical support to help maximize the machine’s capabilities and resolve any issues quickly.

Having a reliable support system ensures your machine runs smoothly throughout its service life, reducing downtime and improving efficiency.

Choosing the right Busbar Punching and Shearing Machine is crucial to improving manufacturing efficiency, reducing costs, and ensuring high-quality production. By focusing on features such as precision, speed, versatility, automation, and energy efficiency, manufacturers can significantly enhance their production lines. Investing in the right machine, backed by solid support and maintenance services, will deliver long-term benefits, allowing you to meet the demands of modern manufacturing while keeping costs in check.

Comente

(0)