In the world of electrical distribution, busbars are fundamental components used to distribute electricity efficiently within electrical panels, switchgear, and distribution boards. As these metal conductors carry high currents, their physical properties and handling characteristics must be precise. One of the critical processes in busbar manufacturing is chamfering. This process, performed by a busbar chamfering machine, involves creating angled or rounded edges on busbars to improve their functionality, handling, and safety.

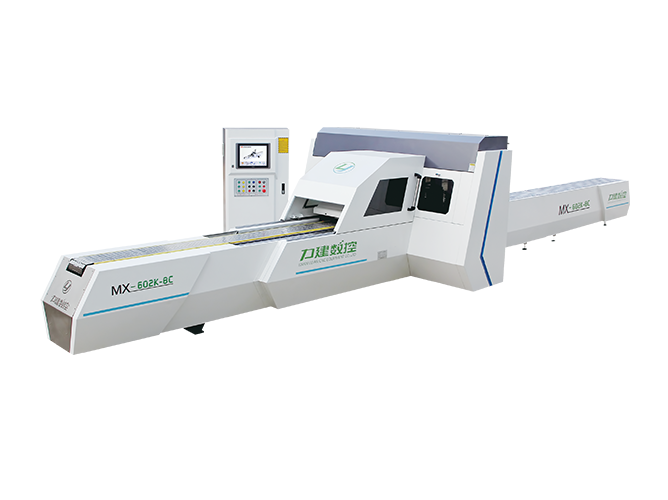

A busbar chamfering machine is an industrial machine designed to bevel the edges of busbars (usually made of copper or aluminum) to a specific angle, typically between 15° and 45°. Chamfering helps remove sharp edges, prevents injuries during handling, and ensures that busbars fit properly in electrical systems. In this article, we’ll explore the purpose, operation, benefits, and types of busbar chamfering machines.

A busbar chamfering machine is a specialized tool used to bevel the edges of busbars, which are metallic strips used for conducting electrical power. Busbars often have sharp edges that could cause issues like injury to operators or improper connections when inserted into electrical panels. A chamfering machine is essential in the manufacturing of busbars as it ensures smooth, safe, and accurate edges for the final product.

The machine uses various methods, including cutting, abrasive grinding, or rotary tools, to produce clean, accurate bevels on the busbar's edges. Chamfering is a necessary step to prevent physical damage, ensure proper electrical connections, and increase the overall durability of the busbars.

A busbar chamfering machine works by cutting, grinding, or beveling the edges of a busbar using specialized tools. Below are the primary steps involved in the chamfering process:

The first step is loading the busbar into the machine. The operator places the busbar into the designated area of the machine, ensuring it is positioned correctly. Depending on the machine type, this step may be automated or done manually.

After loading the busbar, the operator adjusts the machine settings, such as the desired chamfer angle, cutting speed, and depth of cut. Some modern machines, particularly CNC chamfering machines, allow for precise programming of these settings, ensuring that each chamfer meets exact specifications.

Once the settings are adjusted, the machine performs the chamfering operation. This typically involves a rotating cutting tool or abrasive wheel that moves along the edge of the busbar. The tool removes material from the edges, producing a smooth bevel at the desired angle.

The chamfering machine can be configured to cut multiple edges simultaneously, depending on the busbar's size and the machine's capabilities.

After the chamfering operation, some machines have an additional step to remove any remaining burrs or sharp edges that might have resulted from the cutting process. This step is essential to prevent any physical damage during installation and to ensure that the chamfered busbar can fit easily into electrical components.

Finally, the chamfered busbar undergoes quality control checks. Operators or automated systems verify that the chamfer meets the required angle and that the edges are smooth and clean. This ensures that the busbar will function effectively and safely within an electrical system.

When selecting a busbar chamfering machine, several key features should be taken into account to ensure optimal performance and efficiency:

The ability to adjust the chamfer angle is crucial for manufacturing busbars that meet specific requirements. Some machines offer flexibility in angle settings, allowing operators to create chamfers anywhere from 15° to 45°, depending on the needs of the project.

High-precision cutting tools are critical for achieving accurate and smooth chamfers. The quality of the cutting tool can significantly affect the final result. Carbide tips or diamond grinding wheels are often used in chamfering machines for their durability and precision.

The speed at which the chamfering process occurs is another important feature. Faster machines can produce a larger number of chamfered busbars in less time, increasing the overall productivity of the manufacturing process.

Modern busbar chamfering machines often come equipped with CNC controls that enable precise programming of chamfering angles, cutting depth, and other parameters. Automated machines can ensure that all busbars are treated consistently, leading to higher quality and fewer errors.

Safety is a major consideration in industrial machines. Chamfering machines come equipped with safety features such as guards, emergency stops, and operator sensors to protect personnel during operation.

Some chamfering machines include integrated deburring tools to remove any excess material left after the chamfering operation. This feature ensures the busbars are free from rough edges, improving both functionality and safety.

As the chamfering process involves cutting or grinding metal, debris such as chips and dust can accumulate. High-quality busbar chamfering machines include systems for collecting or removing these materials, keeping the workspace clean and preventing damage to other components.

The use of a busbar chamfering machine offers several important advantages for manufacturers and electrical companies:

By removing sharp edges from busbars, chamfering machines prevent injuries to workers during handling and installation. Smooth, beveled edges reduce the risk of cuts and abrasions.

Chamfering ensures that busbars fit precisely into electrical connectors, terminals, and other components. A chamfered busbar allows for better electrical conductivity and reliable performance in electrical circuits.

Chamfered busbars are less prone to corrosion and physical damage. By smoothing the edges, the busbars are better able to withstand wear and tear, extending their lifespan and reducing maintenance costs.

With automated and high-speed chamfering machines, manufacturers can process large batches of busbars quickly. This reduces production time and increases throughput in factories.

Chamfered edges contribute to the busbar’s clean and professional appearance, making it easier for workers to handle and install.

There are various types of busbar chamfering machines available, each suited to different needs and production scales:

Manual chamfering machines require more operator intervention. The operator feeds the busbar into the machine and adjusts the settings manually. While they are simple to operate, these machines can be slower and less precise than automated options.

Semi-automatic chamfering machines offer some automation but still require manual loading and unloading of busbars. These machines allow for faster processing compared to manual machines, with some automated adjustments for angle and cutting depth.

CNC (Computer Numerical Control) busbar chamfering machines are the most advanced option. These machines allow for precise control of the chamfering process and can be programmed to handle multiple busbars at once. CNC chamfering machines offer high accuracy and are ideal for large-scale production runs.

A busbar chamfering machine is a crucial piece of equipment in the busbar manufacturing process. It ensures that busbars have smooth, rounded edges that enhance safety, improve electrical connections, and extend the lifespan of electrical systems. The use of chamfering machines, particularly those with CNC technology, provides manufacturers with precision, efficiency, and flexibility, allowing for high-quality busbars that meet rigorous industrial standards.

By understanding the operation, features, and benefits of busbar chamfering machines, manufacturers can improve their production processes, reduce costs, and ensure that their busbars are ready for use in high-performance electrical applications.

Comente

(0)