Why 3-in-1 busbar machines Are a Must-Have for High-Precision Electrical Projects

In the world of electrical engineering and manufacturing, precision, efficiency, and reliability are paramount. Busbars, which are essential components in electrical power distribution systems, must be fabricated with the utmost accuracy to ensure optimal performance and safety. As technology advances, the demand for high-precision busbar fabrication has grown significantly. This is where 3-in-1 busbar machines come into play. These versatile and advanced machines have become indispensable tools for professionals working on high-precision electrical projects. In this article, we will explore the reasons why 3-in-1 busbar machines are a must-have for such projects, delving into their features, benefits, and the impact they have on the industry.

Understanding Busbars and Their Importance

Before diving into the specifics of 3-in-1 busbar machines, it is essential to understand what busbars are and why they are critical in electrical systems. Busbars are metallic strips or bars, typically made of copper or aluminum, that conduct electricity within a switchboard, distribution board, or other electrical assemblies. They serve as a central hub for power distribution, connecting multiple circuits and ensuring efficient transmission of electrical energy.

Busbars are used in a wide range of applications, from residential and commercial buildings to industrial facilities and power plants. Their design and fabrication must meet stringent standards to ensure they can handle the required electrical load, minimize energy loss, and prevent overheating or short circuits. Given their critical role, the precision and quality of busbar fabrication directly impact the performance and safety of electrical systems.

The Evolution of Busbar Fabrication

Traditionally, busbar fabrication involved multiple steps and separate machines for punching, bending, and cutting. This process was not only time-consuming but also prone to errors, especially when dealing with complex designs or high-volume production. Manual intervention at each stage increased the risk of inaccuracies, leading to suboptimal performance or even system failures.

To address these challenges, the industry has seen the development of integrated busbar machines that combine multiple functions into a single unit. Among these, 3-in-1 busbar machines have emerged as a game-changer, offering unparalleled efficiency, precision, and versatility.

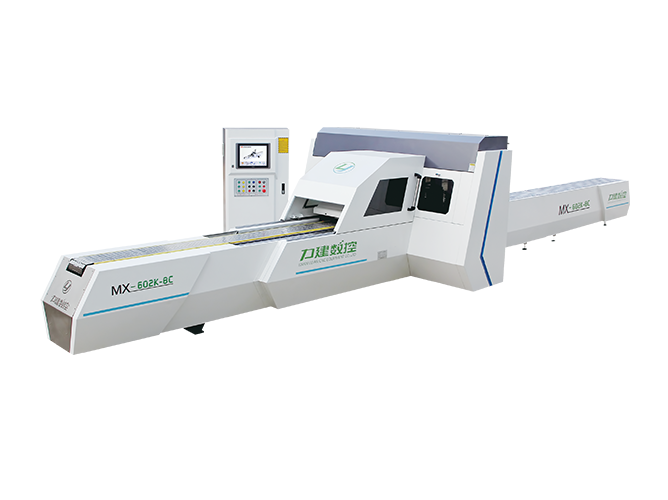

What Are 3-in-1 Busbar Machines?

As the name suggests, 3-in-1 busbar machines integrate three essential functions—punching, bending, and cutting—into a single machine. This all-in-one design eliminates the need for separate equipment, streamlining the fabrication process and reducing the risk of errors. These machines are equipped with advanced features such as CNC (Computer Numerical Control) technology, automated tool changers, and precision sensors, enabling them to handle complex designs with ease.

Key Features of 3-in-1 Busbar Machines

1. CNC Technology: CNC technology is at the heart of 3-in-1 busbar machines, allowing for precise control over the fabrication process. Operators can program the machine to perform specific tasks, ensuring consistent and accurate results. CNC systems also enable the machine to handle intricate designs that would be challenging or impossible to achieve manually.

2. Automated Tool Changers: Many 3-in-1 busbar machines come with automated tool changers, which allow the machine to switch between different tools (e.g., punches, dies, and bending tools) without manual intervention. This feature significantly reduces downtime and increases productivity, especially in high-volume production environments.

3. High Precision Sensors: Precision sensors are integrated into the machine to monitor and adjust the fabrication process in real-time. These sensors ensure that each busbar is fabricated to the exact specifications, minimizing the risk of errors and ensuring consistent quality.

4. Versatility: 3-in-1 busbar machines are highly versatile, capable of handling a wide range of busbar sizes, thicknesses, and materials. This flexibility makes them suitable for various applications, from small-scale projects to large-scale industrial production.

5. User-Friendly Interface: Despite their advanced capabilities, 3-in-1 busbar machines are designed with user-friendly interfaces that make them accessible to operators of all skill levels. Intuitive controls and graphical displays simplify the programming and operation of the machine, reducing the learning curve and minimizing the risk of errors.

Benefits of 3-in-1 Busbar Machines in High-Precision Electrical Projects

1. Enhanced Precision and Accuracy: One of the most significant advantages of 3-in-1 busbar machines is their ability to deliver high precision and accuracy. The integration of CNC technology and precision sensors ensures that each busbar is fabricated to the exact specifications, reducing the risk of errors and ensuring consistent quality. This level of precision is crucial in high-precision electrical projects, where even minor deviations can lead to performance issues or safety concerns.

2. Increased Efficiency and Productivity: By combining three essential functions into a single machine, 3-in-1 busbar machines significantly reduce the time and effort required for busbar fabrication. Automated tool changers and CNC programming further enhance efficiency by minimizing downtime and streamlining the production process. This increased efficiency translates to higher productivity, allowing manufacturers to meet tight deadlines and handle larger volumes of work.

3. Cost Savings: While the initial investment in a 3-in-1 busbar machine may be higher than traditional equipment, the long-term cost savings are substantial. The integration of multiple functions reduces the need for separate machines, lowering equipment and maintenance costs. Additionally, the increased efficiency and reduced risk of errors result in lower labor costs and fewer material wastage, further contributing to cost savings.

4. Improved Safety: Safety is a critical consideration in electrical projects, and 3-in-1 busbar machines contribute to a safer working environment. The automation of the fabrication process reduces the need for manual intervention, minimizing the risk of accidents and injuries. Additionally, the precision and accuracy of these machines ensure that busbars are fabricated to the highest standards, reducing the risk of electrical failures or hazards.

5. Versatility and Flexibility: The versatility of 3-in-1 busbar machines makes them suitable for a wide range of applications, from simple designs to complex, high-precision projects. This flexibility allows manufacturers to adapt to changing project requirements and handle diverse client needs without the need for additional equipment. The ability to work with various materials and sizes further enhances the machine's versatility, making it a valuable asset in any electrical fabrication workshop.

6. Consistency and Quality Control: Consistency is key in high-precision electrical projects, and 3-in-1 busbar machines excel in delivering consistent results. The CNC programming and precision sensors ensure that each busbar is fabricated to the same high standards, regardless of the volume of production. This consistency is crucial for maintaining quality control and ensuring that all components meet the required specifications.

7. Reduced Lead Times: In today's fast-paced industry, reducing lead times is essential for staying competitive. 3-in-1 busbar machines enable manufacturers to complete projects more quickly by streamlining the fabrication process and minimizing downtime. The ability to handle complex designs with ease further reduces lead times, allowing manufacturers to deliver high-quality products to their clients in a timely manner.

Applications of 3-in-1 Busbar Machines

The versatility and precision of 3-in-1 busbar machines make them suitable for a wide range of applications in the electrical industry. Some of the key applications include:

1. Power Distribution Systems: Busbars are a critical component in power distribution systems, and 3-in-1 busbar machines are ideal for fabricating the precise and reliable busbars needed for these systems. Whether it's for residential, commercial, or industrial applications, these machines ensure that the busbars meet the required standards for performance and safety.

2. Switchgear and Control Panels: Switchgear and control panels require busbars that can handle high electrical loads and ensure efficient power distribution. 3-in-1 busbar machines are capable of fabricating busbars with the precision and accuracy needed for these applications, ensuring that the panels operate smoothly and safely.

3. Renewable Energy Systems: The growing demand for renewable energy systems, such as solar and wind power, has increased the need for high-precision busbars. 3-in-1 busbar machines are well-suited for fabricating the busbars used in these systems, ensuring that they can handle the unique requirements of renewable energy applications.

4. Industrial Machinery: Industrial machinery often requires complex and high-precision busbars to ensure efficient power distribution and operation. 3-in-1 busbar machines are capable of handling the intricate designs and high volumes needed for industrial applications, making them a valuable asset in manufacturing facilities.

5. Transportation and Automotive: The transportation and automotive industries also rely on busbars for various applications, including electric vehicles and rail systems. 3-in-1 busbar machines are capable of fabricating the precise and reliable busbars needed for these industries, ensuring that the systems operate efficiently and safely.

Conclusion

In conclusion, 3-in-1 busbar machines have become an essential tool for high-precision electrical projects, offering a range of benefits that enhance efficiency, accuracy, and safety. Their ability to integrate multiple functions into a single machine, combined with advanced features such as CNC technology and automated tool changers, makes them a must-have for manufacturers and electrical engineers. The versatility, cost savings, and consistent quality provided by these machines ensure that they can meet the diverse needs of the electrical industry, from power distribution systems to renewable energy applications.

As the demand for high-precision busbars continues to grow, 3-in-1 busbar machines will play an increasingly important role in ensuring that electrical systems are fabricated to the highest standards. By investing in these advanced machines, manufacturers can stay ahead of the competition, deliver high-quality products, and contribute to the safe and efficient distribution of electrical power. Whether you are working on a small-scale project or a large-scale industrial application, a 3-in-1 busbar machine is a valuable asset that can help you achieve your goals with precision and efficiency.

Comente

(0)